Industrial vs Residential Control Panels

- mktg743

- Jul 16

- 2 min read

In today's world, control panels are vital components in both industrial and

residential settings. These panels serve as the central hub for managing electrical

systems, ensuring safety, and optimizing performance. However, industrial and

residential control panels have distinct differences that cater to their specific

environments and applications. Understanding these differences is crucial for

selecting the right type of panel for your needs. In this article, we'll explore the key

distinctions between industrial and residential control panels, their components,

and their applications.

Before diving into the specifics, it's essential to understand what control panels are and their basic functions. Control panels are assemblies of electrical devices that manage and regulate electrical power in a system. They house various components such as circuit breakers, switches, relays, and wiring. Control panels ensure the

safe distribution of electricity, protect electrical circuits from overload, and provide a convenient interface for monitoring and controlling electrical systems.

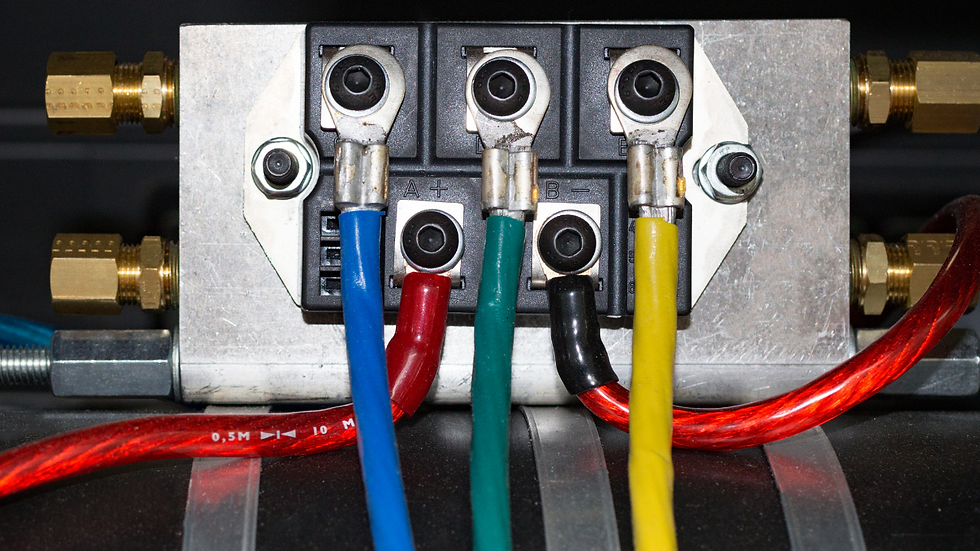

Industrial Control Panels

Industrial control panels are designed for use in factories, manufacturing plants, and other industrial environments. These panels are built to withstand harsh

conditions and heavy usage. They play a critical role in automating processes,

controlling machinery, and ensuring the efficient operation of industrial systems.

Key Features of Industrial Control Panels

Durability and Robustness: Industrial control panels are constructed using high-quality materials that can endure extreme temperatures, moisture, dust, and

vibrations. This durability ensures they can operate reliably in demanding

environments.

Complexity and Customization: These panels often have complex

configurations with multiple components tailored to specific industrial

processes. They can be customized to meet the unique requirements of

different industries.

Advanced Control Systems: Industrial panels integrate advanced control

systems and software for automation and precision. They often include

programmable logic controllers (PLCs) and human-machine interfaces (HMIs) to facilitate efficient monitoring and control.

Applications of Industrial Control Panels

Industrial control panels are used in a wide range of applications, including:

Manufacturing: Controlling assembly lines, robotic systems, and production

machinery.

Energy: Managing power distribution and generation systems in energy plants.

Chemical Processing: Monitoring and controlling chemical reactions and

processes.

Water Treatment: Regulating pumps, valves, and filtration systems in water

treatment facilities.

Residential Control Panels

Residential control panels are made for homes and small buildings. They have a simpler design than industrial panels. Their main goal is to ensure safe electricity distribution in a residential property.

Key Features of Residential Control Panels

Simplicity and Accessibility: Residential panels are straightforward and easy to use, often requiring minimal maintenance. They are designed for easy access

to circuit breakers and fuses for quick troubleshooting.

Standardization: These panels adhere to standard configurations and comply with residential electrical codes. They are typically equipped with standard

circuit breakers and switches.

Safety: Residential panels focus on safety. They have features like ground fault circuit interrupters (GFCIs) and arc fault circuit interrupters (AFCIs). These features help protect against electrical hazards.

Applications of Residential Control Panels

Residential control panels are essential for:

Home Electrical Systems: Distributing power to lighting, appliances, and

outlets.

Safety Systems: Supporting smoke detectors, security systems, and

emergency lighting.

Renewable Energy Integration: Managing connections to solar panels and backup generators.

Three-Phase Power for Industrial Control Panels

Industrial control panels usually use three-phase power. This is a way to transmit electrical power. It involves three alternating currents (AC) that have the same frequency. These currents are separated by 120 degrees. This system is made to provide a steady flow of power. It is perfect for industrial settings where efficiency and reliability are very important.

Key Advantages of Three-Phase Power:

Efficiency: Three-phase systems provide more power using less wire than single-phase systems. This reduces energy loss and lowers wiring costs. This is particularly important in environments where energy efficiency

can lead to significant cost savings.

Power Stability: Three-phase systems provide steady and balanced power. This ensures that heavy machinery and equipment operate smoothly. In industrial settings, where operational disruptions can lead to

downtime and financial losses, this stability is critical.

Higher Power Density: Industrial control panels that use three-phase power can handle larger electrical loads. This is important for heavy machinery, motors, and other industrial equipment that need more power.

Applications of Three-Phase Power in Industrial Control Panels:

Motor Control: Many industrial machines and motors require three-phase power for optimal performance. Control panels are designed to manage the starting, stopping, and operation of these motors effectively.

Automation Systems: Advanced automation systems in factories use three-phase power. This ensures a steady power supply and reliable operation

automated processes.

High-Power Equipment: Equipment like compressors, pumps, and welding machines usually run on three-phase power. This means industrial control panels must support this type of electrical supply.

Single-Phase Power for Residential Control Panels

In contrast, residential control panels are generally powered by single-phase power. This system consists of a single alternating current, which is

sufficient for the lower power demands of home environments.

Key Characteristics of Single-Phase Power:

Simplicity: Single-phase systems are easier to design. They work well for common home needs, like powering appliances, lights, and electronics.

Lower Power Capacity: Single-phase systems are cheap and easy to install. However, they cannot handle the high power needs of heavy machines and industrial processes. This limitation makes them less suitable for applications that

demand significant energy.

Standardization: Residential panels follow standardized configurations and

comply with local electrical codes, focusing on safety and functionality for

everyday household use.

Industrial vs Residential Control Panels: Key Differences

Environment and Usage

Industrial control panels are made for tough environments with heavy use. In contrast, residential panels are designed for regular home settings with lighter use.

Complexity and Customization

Industrial panels can be customized a lot and can manage complex systems. In contrast, residential panels are more standard and simpler in design.

Components and Technology

Industrial panels incorporate advanced technology like PLCs and HMIs, whereas

residential panels focus on basic safety and functionality components.

Cost and Maintenance

Industrial panels are generally more expensive due to their complexity and

durability. They may also require specialized maintenance. Residential panels are

more cost-effective and easier to maintain.

Comments