Industrial Control Panel Power Distribution and Conditioning

- mktg743

- Aug 21, 2025

- 3 min read

What This Article Covers

In this article, we’ll break down the essentials of how electrical power flows through industrial control panels, including:

The role of codes and standards (NEC, UL 508A, etc.)

Key functions and components found in control panels

Typical voltage levels and their applications

Differences between transformers, power supplies, inverters, and converters

The importance of surge suppression, power conditioning, line filters, and reactors

A practical example of control panel power distribution design

Introduction

When electrical power enters an industrial control panel, it often does so through one or more main circuits. That power must be properly converted, protected, and distributed to meet the needs of the connected equipment.

Nearly all control panels—especially those listed under UL 508A—are designed with incoming power circuits and an internal distribution system. Within these systems, various components are responsible for:

Protecting against overcurrent

Routing and transmitting power

Converting between voltages

Guarding equipment against surges

Smoothing and conditioning the quality of the power

Common Control Panel Functions and Components

Industrial control panels are versatile systems that may include a combination of:

Power distribution systems

Voltage conversion and power supplies

Motor starters and variable frequency drives (VFDs)

Lighting contactors

Relay-based hardwired controls

Electronic controls (PLCs, HMIs, smart devices)

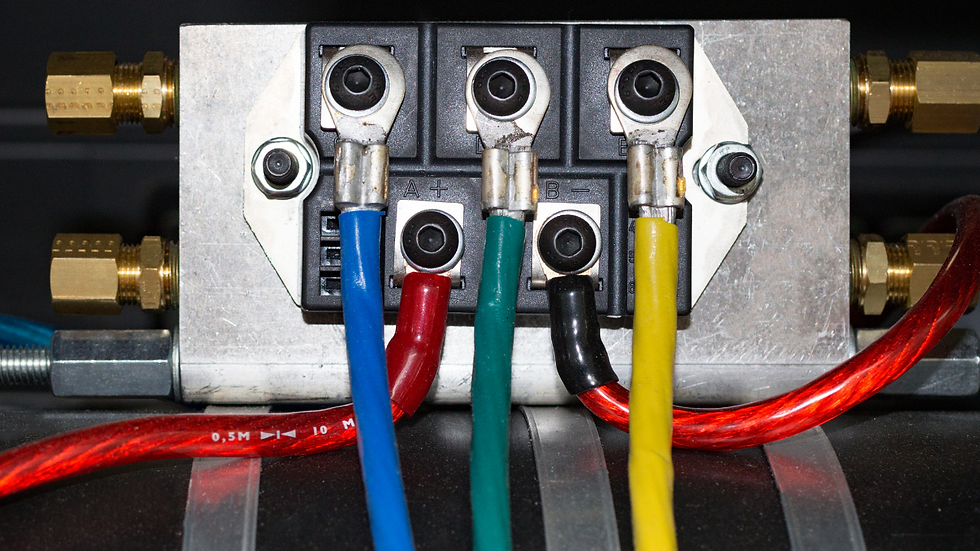

Pneumatic solenoids

Instrumentation for monitoring and measurement

Compliance and Standards

All aspects of control panel electrical design must comply with relevant codes (such as the NEC) and standards (such as UL 508A). Key principles include:

Component selection: Use only parts rated for the intended service, from active devices like power supplies to passive parts like terminal blocks.

Overcurrent protection: Properly size fuses and circuit breakers per NEC requirements to protect downstream equipment.

Conductor sizing: Select wires, cables, and terminals that can safely supply the intended load.

Typical Voltage Levels in Control Panels

Control panels in North America commonly use the following voltages:

480 Vac 3-phase (277 Vac 1-phase): Typical for industrial motors; 277 Vac sometimes used for lighting.

208 Vac 3-phase (120 Vac 1-phase): Common in commercial buildings; often used for air conditioning motors and receptacles.

125 Vdc: Used in large switchgear with battery banks to ensure continued operation during outages.

120-240 Vac 1-phase (3-wire): Standard in residential applications—240 Vac for heavy appliances, 120 Vac for general outlets and lights.

120 Vac: The most widely used voltage for general-purpose equipment.

24 Vdc: A “touch-safe” control voltage, widely used in automation and often installed redundantly for reliability.

24 Vac: Popular in HVAC and refrigeration controls, often as NEC Class 2 circuits for easier field wiring.

Transformers, Power Supplies, Inverters, and Converters

Different devices manage the conversion of power inside panels:

Transformers: Step AC voltages up or down; they can be bulky and generate heat, so external mounting is preferred when possible.

Power supplies: Convert AC to DC; often provide redundancy and diagnostic contacts for system monitoring.

Inverters: Convert DC back into AC; used less frequently in panel applications.

Converters: Shift one DC voltage to another; also less common but useful in specialized cases.

Surge Suppression, Power Conditioning, Line Filters, and Reactors

Protecting sensitive electronics is critical. Here’s how different devices help:

Surge suppressors: Divert harmful surges (like lightning strikes) to ground, protecting delicate electronics.

Power conditioners: Smooth voltage fluctuations and ensure stable power for sensitive devices like PLCs and power supplies.

Line filters and reactors: Especially important with VFDs, which generate electrical noise. These devices reduce interference and protect upstream systems.

Practical Example: Control Panel Power Distribution

A typical industrial control panel may use a combination of the devices above. For instance:

Incoming 480 Vac feeds motor starters, VFDs (protected by line filters or reactors), and a transformer.

The transformer steps down to 120 Vac, which is surge suppressed.

That 120 Vac feeds PLCs, power supplies, and HMIs, or is further converted down to 24 Vdc for low-voltage automation devices.

Comments