Infinity Industrial Controls, Inc. designs, manufactures, delivers, and maintains Turnkey Automation Systems. Our engineers and service technicians diagnose, troubleshoot, and repair drives, motors, PLC, and control panel rewiring. Since 2010, Infinity’s expertise ranges - from providing service to power authorities and transport agencies to OEM machine building for fiber optics manufacturers.

Metal Coating Line

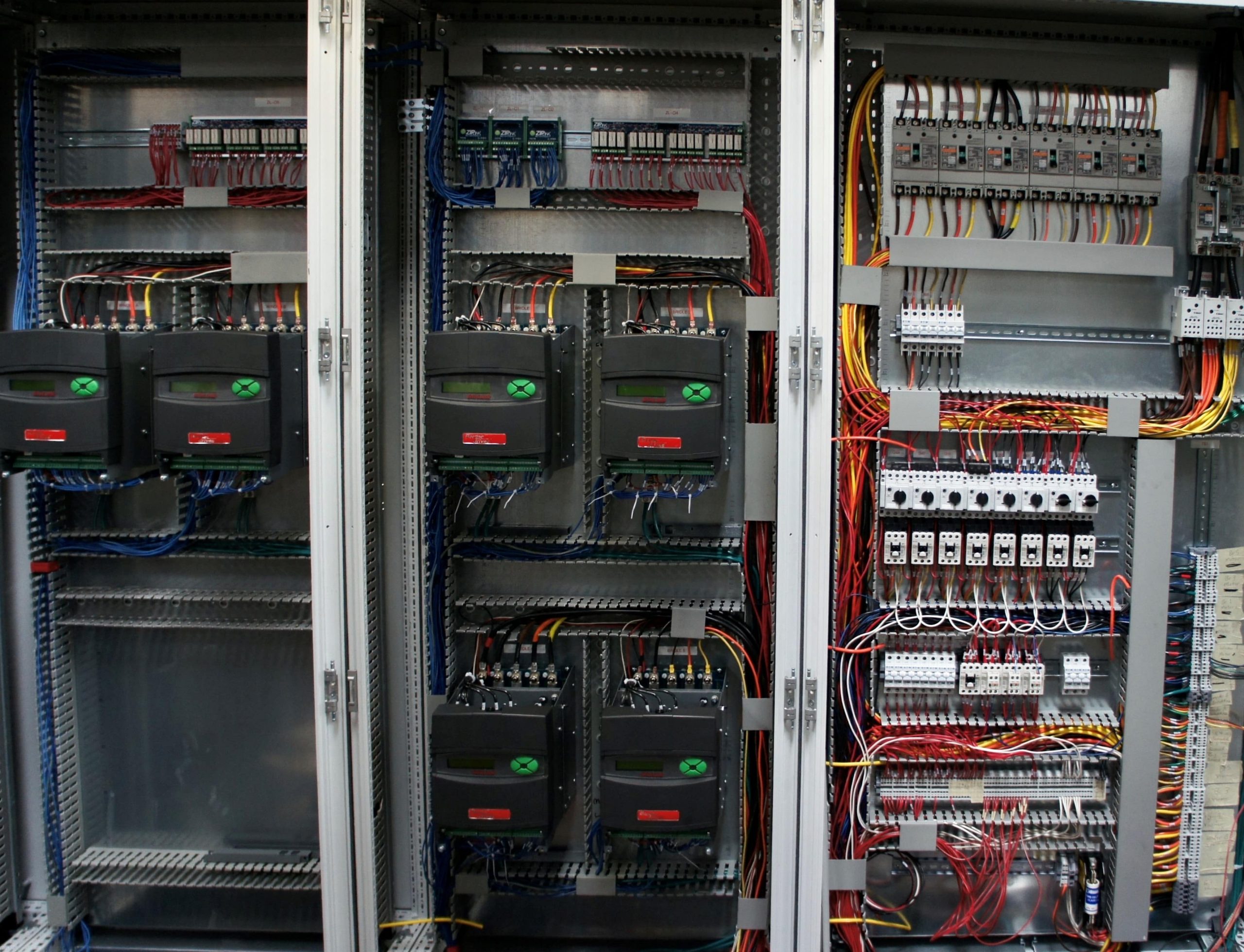

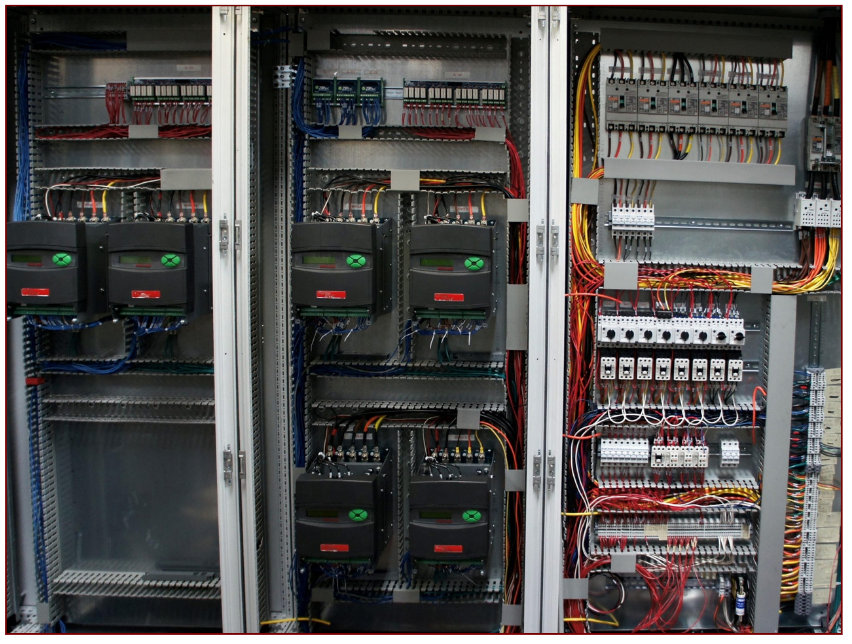

Built in 1987, this coil coating machine is over 400 feet long, and over 30 feet high. A complex mesh of mechanical, electronic and software, the massive machine uncoils 3,000 pound reels of steel or aluminum, threads it through 400 feet of rollers, over-head and under the floor, washes, dries, primes and paints every square inch, then recoils it non-stop. The factory was recently purchased after a long period of poor maintenance and neglect. The new owner called Infinity to get this coil coating line running at peak efficiency. This meant tearing out tons of old wiring, controls, motors and gearboxes and installing new ones.

By the end of the project, this machine was running smoothly just in time for the rush of orders from hurricane Sandy. Infinity provided a mix of mechanical, electrical and programming talent needed to get this machine painting metal. Replacing broken analog gauges, and shaky consoles with two shiny new control panels with state-of-the-art touch screen interfaces, this now NEW machine will provide years of reliable service.

Rail Bridges

This railroad bridge has a 60 year old wound rotor motors. Without the bridge being in service, the barges on the Mississippi River cannot move past the bridge and the trains cannot cross the river. The project was 3 weeks overdue when we were called in. The customer did not want to change out the entire system due to the extreme cost. Two JLXD microprocessor controllers were married to the existing technology to control 2 wound rotor motors used to raise and lower the bridge. The JLXD is a wound rotor compatible with the Bardac drive.

This pilot project had numerous problems adapting state-of-the-art technology to the existing application. This was the first time that high-speed microprocessor controllers were adapted to wound rotor motors. We created custom software to balance the load sharing of the 2 motors and provide tach loss feedback circuits on the master and slave configuration. Infinity Industrial Controls’ vast knowledge and experience of motor and drive technology made the success of this project possible. The rail bridge was operational within one week of Infinity Industrial Controls arriving on- site.

Stacker Reclaimers

The barge unloader had been down for 8 days. Without the unloader running, there were 5 barges stacking up in the Gulf of Mexico filled with coal. The EPA levies fines for sitting fossil fuel vessels at $250,000 per day/per barge.

The customer had called out three different drive vendors over the course of this 8 day catastrophe. The barge unloader drives had numerous issues including mismatched cards. We correctly replaced the cards, repaired the drive and did the start-up. The barge unloader was functional within 2 hours of our arrival. Top management was on-site to thank us for responding so quickly and putting an end to the $1.25 million in penalties per day.

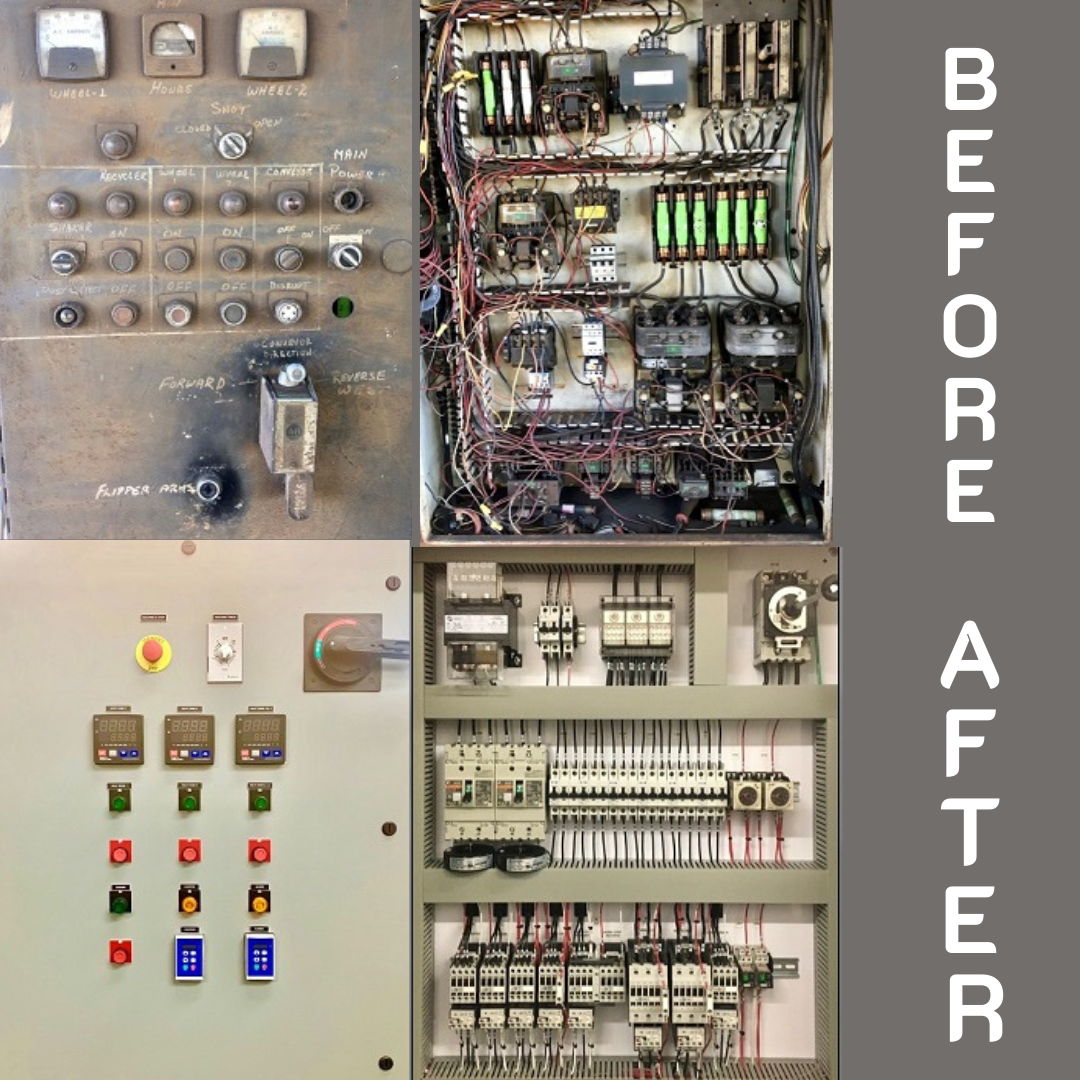

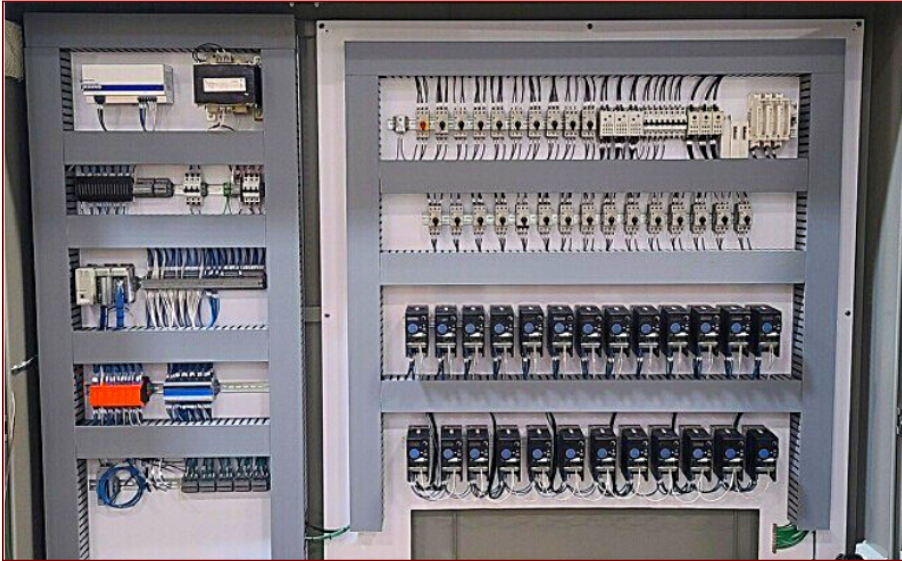

Machine Retrofit Services

Making your old machines new again, Infinity Industrial will refurbish and retrofit your aging equipment. This saves you time on long lead times of new machines. It saves you money, as a robust retrofit is often 1/3 the cost of new machines. This increases your productivity and your bottom line. We can create a brand-new control panel with custom PLC programming with process driven recipes specific to your exact needs. We can simplify your program as well, unlike some proprietary programs that are too over complex. We handle all electrical and mechanical issues including creating new complete AutoCAD drawings that provide a pathway for any future troubleshooting or repairs. From extruders to presses, from paint lines to wheelabrators, there isn’t a machine we can’t fix.